I-Industrial High Purity High Pressure ye-Oxygen Helium Diaphragm Compressor

Xuzhou Huayan Gas Equipment Co., Ltd.ngumboneleli wehlabathi jikelele wezisombululo zoxinzelelo lwegesi. Ngobuchule obuqokelelweyo bokuyila kunye nokuvelisa amashumi eminyaka, inkampani yethu inamandla okuvelisa abanzi abandakanya ukubunjwa kobuchwephesha, ukuphosa, unyango lobushushu, ukuwelda, ukuchaneka komatshini, uvavanyo lwendibano, kunye neenkqubo zokuqinisekisa umgangatho. Sixhaswa liqela elizinikeleyo lobuchwephesha eliziingcali ezili-120 kunye neziko lokuvelisa elithe kratya elingama-90,000 m², sigcina izixhobo zovavanyo olukwizinga eliphezulu kunye neendlela ezingqongqo zolawulo lomgangatho ukuqinisekisa ukusebenza kwemveliso okugqwesileyo.

Iyakwazi ukuyila, ukuvelisa, kunye nokufaka izixhobo ngokwemimiselo ethile yabathengi, okwangoku sifezekisa umthamo wonyaka wemveliso yeeyunithi ezingama-500 zegesi. Ukugqwesa kwethu kwezobuchwephesha kuvumela uphuhliso lweecompressor kunye noxinzelelo lokukhupha ukuya kuthi ga kwi-100MPa, ukuhlangabezana nezona mfuno zinzima zoshishino.

Ngomkhondo wehlabathi lonke ofikelela kumazwe angaphezu kwama-50 kumazwekazi amahlanu, kubandakanya iimarike eziphambili ezifana ne-Indonesia, iYiphutha, iVietnam, iSouth Korea, iThailand, iFinland, iOstreliya, iRiphabliki yaseCzech, iUkraine, kunye neRussia, sinikezela ngezisombululo ezipheleleyo zokujika kubathengi kwihlabathi liphela. Ukuzibophelela kwethu ekugqweseni kokusebenza kuqinisekisa ukuba wonke umthengi ufumana izixhobo zokusebenza eziphezulu ezidityaniswe nenkxaso yobuchwephesha bobuchwephesha kunye nenkonzo ephendulayo.

SQUARE imitha

IQELA LEZOBUGCISA

AMAVA OKWENZA

AMAZWE ATHUNYELWAYO

A i-compressor ye-diaphragmsisicinezeli esikhethekileyo sokufuduka esidume ngokukwazi ukuphatha iigesi ngobunyulu obukhethekileyo, ubuntununtunu, okanye ingozi ngaphandle kosulelo okanye ukuvuza. Ngokungafaniyo neecompressor zepiston zesiko, isebenzisa idiaphragm eguquguqukayo, ene-hydraulically actuated ukwahlula igesi ecinezelweyo kwicrankcase kunye nepiston.

Ezona mpawu:

1,Ukutywinwa kweHermetic: Isinyithi okanye i-elastomer diaphragm idala umqobo opheleleyo, ongenakuvuza phakathi kwegesi kunye ne-hydraulic fluid / lubricant. Olu luphawu oluchazayo.

2,Zero Usulelo: Iqinisekisa ukuba irhasi ecinezelweyo ihlala ingenaoyile ngokupheleleyo kwaye ingangcoliswanga zizithambiso okanye amasuntswana anxitywayo asuka kumatshini wokuqhuba. Kubalulekile kwizicelo ezicocekileyo.

3,UkuThintela ukuvuza: Susa izinto ezikhutshwayo ezibalekayo, oko kuyenza ibaluleke kakhulu ekuphatheni iigesi eziyityhefu, ezinokutsha, eziqhumayo, okanye ezinobungozi kokusingqongileyo.

4,Ubunakho boxinzelelo oluphezulu: Iyakwazi ukufezekisa uxinzelelo oluphezulu kakhulu lokukhupha (ngokuphindaphindiweyo ukuya kwi-3000 bar / 43,500 psi nangaphezulu), ngokukodwa kwimimiselo yamanqanaba amaninzi.

5,UkuPhathwa kweGesi ngeendlela ezininzi: Ilungele ukucinezela uluhlu olubanzi lweegesi, kubandakanywa ukuphinda kusebenze kakhulu, ukubola, ukuhlanjululwa kwe-ultra-pure, ixabiso elibi, okanye ubungozi obunokonakalisa okanye ungcoliseko lolunye uyilo lwecompressor.

6Amaxabiso okuHamba okuPhakathi: Ngokuqhelekileyo yenzelwe amazinga okuhamba aphantsi ukuya aphakathi xa kuthelekiswa ne-reciprocating enkulu okanye i-centrifugal compressors.

Iigesi ezifanelekileyo

Iigesi ezifanelekileyo

1. Ubomi benkonzo ende

Izinto eziphathekayo zentloko ye-cylinder ye-compressor ye-diaphragm zenziwe kwaye zicutshungulwe, kwaye emva kokunyangwa kobushushu, izinto eziphathekayo zinokumelana noxinzelelo oluphezulu, ukwandisa ubomi benkonzo yezixhobo ubuncinane iminyaka engama-20.

2. Ukuchasa ukuMhlwa

Umbhobho we-compressor ye-diaphragm yenziwe nge-SS304 okanye i-SS316L yensimbi engenasici, eyandisa ukunyanzeliswa kwe-corrosion yezixhobo kwiindawo ezifumileyo kunye ne-acidic, ngaphandle kokugqwala, kwaye inkangeleko entle.

3. Uxinzelelo oluphezulu lokukhupha

Uxinzelelo lwe-exhaust ye-compressor ye-diaphragm inokufikelela kwi-90MPa.

4, Ubomi benkonzo ende yamalungu asemngciphekweni

Kwiicompressor ezipholileyo zamanzi, kukho imingxuma emi-5 yomjelo wamanzi kwintloko yesilinda. Ukongeza kwi-cooler yangaphandle yamanzi enciphisa ukushisa kwegesi, sipholise intloko ye-cylinder ukunciphisa igesi kunye nokwandisa ubomi benkonzo ye-diaphragm kunye ne-valve. Ubomi obuqhelekileyo benkonzo ye-diaphragm bunokufikelela ngaphezu kwe-5000h.

5. Ukusebenza kakuhle kokutywina

Intloko ye-cylinder iyilwe ngokusisiseko kunye nokufakelwa kwe-O-ring edibeneyo, kwaye umphumo wokutywina uphezulu kakhulu kunentloko ye-membrane evulekile.

1,Petrochemical & Chemical Processing: Ukunyanzeliswa kweziphakathi ezinobungozi kakhulu, i-reactants enetyhefu (umzekelo, kwimveliso ye-PVC nge-Cl₂), i-catalyst regeneration gases, i-hydrogen compression ye-hydrocrackers / i-hydrotreaters apho ubunyulu bubaluleke kakhulu.

2,I-oyile neGesi: Ukunyanzeliswa kwegesi ye-Subsea, i-injection yegesi (i-oyile ephuculweyo yokubuyisela), i-hydrogen compression for refineries.

3,Ukwenziwa kweSemiconductor: Kubalulekile ukubonelela nge-ultra-high purity (UHP) kunye neegesi ezikhethekileyo ezinobungozi (ezifana ne-ASH₃, PH₃, SiH₄) kwizixhobo zokwenza ngaphandle kokungcola.

4,Uhlalutyo kunye neLebhu: Ukubonelela ngeegesi ezicocekileyo, ezingenazingcolisi, iigesi zokulinganisa, kunye neesampulu zeegesi zezixhobo ezifana ne-GC-MS.

5,I-Aerospace kunye noVavanyo: Ukunikezelwa kwegesi ephezulu (Yena, N₂) yokuvavanya amacandelo e-rocket, iinkqubo zoxinzelelo, imigudu yomoya.

6EzoNyango kunye nezoNyango: Ukuveliswa kunye neebhotile zeegesi zonyango ezicocekileyo (O₂, N₂O), umoya oyinyumba kwiinkqubo.

7.Ishishini leNyukliya: Ukuphatha izinto zokupholisa zehelium okanye iigesi zokuvala.

8,Amandla kunye neHydrojeni: Uxinzelelo lweHydrogen kwiiseli zamafutha, izikhululo ze-hydrogen refueling (HRS), kunye nokuveliswa kwe-hydrogen / uphando lokugcina.

9,Ubuchwephesha bokuSingqongileyo: Ukucinezela i-CO₂ yokubamba okanye ukusetyenziswa (CCUS).

| Umzekelo | Ukusetyenziswa kwamanzi okupholisa (t/h) | Ukufuduswa (Nm³/h) | Uxinzelelo lokuthatha (MPa) | Uxinzelelo lwe-exhaust (MPa) | Imilinganiselo L×W×H(mm) | Ubunzima (t) | Amandla eMoto (kW) | |

| 1 | GL-10/160 | 1 | 10 | 16 | 2200×1200×1300 | 1.6 | 7.5 | |

| 2 | GL-25/15 | 1 | 25 | 1.5 | 2200×1200×1300 | 1.6 | 7.5 | |

| 3 | GL-20/12-160 | 1 | 20 | 1.2 | 16 | 2200×1200×1300 | 1.6 | 7.5 |

| 4 | GL-70/5-35 | 1.5 | 70 | 0.5 | 3.5 | 2000×1000×1200 | 1.6 | 15 |

| 5 | GL-20/10-150 | 1.5 | 20 | 1.0 | 15 | 2200×1200×1300 | 1.6 | 15 |

| 6 | GL-25/5-150 | 1.5 | 25 | 0.5 | 15 | 2200×1200×1300 | 1.6 | 15 |

| 7 | GL-45/5-150 | 2 | 45 | 0.5 | 15 | 2600×1300×1300 | 1.9 | 18.5 |

| 8 | GL-30/10-150 | 1.5 | 30 | 1.0 | 15 | 2300×1300×1300 | 1.7 | 11 |

| 9 | GL-30/5-160 | 2 | 30 | 0.5 | 16 | 2800×1300×1200 | 2.0 | 18.5 |

| 10 | GL-80/0.05-4 | 4.5 | 80 | 0.005 | 0.4 | 3500×1600×2100 | 4.5 | 37 |

| 11 | GL-110/5-25 | 1.4 | 110 | 0.5 | 2.5 | 2800×1800×2000 | 3.6 | 22 |

| 12 | GL-150/0.3-5 | 1.1 | 150 | 0.03 | 0.5 | 3230×1770×2200 | 4.2 | 18.5 |

| 13 | GL-110/10-200 | 2.1 | 110 | 1 | 20 | 2900×2000×1700 | 4 | 30 |

| 14 | I-GL-170/2.5-18 | 1.6 | 170 | 0.25 | 1.8 | 2900×2000×1700 | 4 | 22 |

| 15 | I-GL-400/20-50 | 2.2 | 400 | 2.0 | 5.0 | 4000×2500×2200 | 4.5 | 30 |

| 16 | I-GL-40/100 | 3.0 | 40 | 0.0 | 10 | 3700×1750×2000 | 3.8 | 30 |

| 17 | GL-900/300-500 | 3.0 | 900 | 30 | 50 | 3500×2350×2300 | 3.5 | 55 |

| 18 | GL-100/3-200 | 3.5 | 100 | 0.3 | 20 | 3700×1750×2150 | 5.2 | 55 |

| 19 | I-GL-48/140 | 3.0 | 48 | 0.0 | 14 | 3800×1750×2100 | 5.7 | 37 |

| 20 | GL-200/6-60 | 3.0 | 200 | 0.6 | 6.0 | 3800×1750×2100 | 5.0 | 45 |

| 21 | I-GL-140/6-200 | 5.0 | 140 | 0.6 | 20.0 | 3500×1380×2350 | 4.5 | 55 |

| 22 | GL-900/10-15 | 2.5 | 900 | 1.0 | 1.5 | 3670×2100×2300 | 6.5 | 37 |

| 23 | GL-770/6-20 | 4.5 | 770 | 0.6 | 2.0 | 4200×2100×2400 | 7.6 | 55 |

| 24 | GL-90/4-220 | 6.0 | 90 | 0.4 | 22.0 | 3500×2100×2400 | 7.0 | 45 |

| 25 | I-GL-1900/21-30 | 3.8 | 1800 | 2.1 | 3.0 | 3700×2000×2400 | 7.0 | 55 |

| 26 | GL-300/20-200 | 4.2 | 300 | 2.0 | 20.0 | 3670×2100×2300 | 6.5 | 45 |

| 27 | GL-200/15-200 | 4.0 | 200 | 1.5 | 20.0 | 3500×2100×2300 | 6.0 | 45 |

| 28 | GL-330/8-30 | 5.0 | 330 | 0.8 | 3.0 | 3570×1600×2200 | 4.0 | 45 |

| 29 | GL-150/6-200 | 5.0 | 150 | 0.6 | 20.0 | 3500×1600×2100 | 3.8 | 55 |

| 30 | GL-300/6-25 | 4.5 | 300 | 0.6 | 2.5 | 3450×1600×2100 | 4.0 | 45 |

Sibambe izatifikethi ezamkelwa kumazwe ngamazwe kuqukaCEkwayeISOimigangatho (ivunywe nguIAF), njengoI-ECMukuqatshelwa kokuthotyelwa. Ezi zatifikethi zibonisa ukuzinikela kwethu okungagungqiyo kumgangatho, ukhuseleko, kunye noxanduva lokusingqongileyo:

- CE Ukumakishwaiqinisekisa ukuthotyelwa kwe-EU yokhuseleko, impilo, kunye nemigaqo yokusingqongileyo, iqinisekisa ukufikelela kwiimarike zaseYurophu kulo lonke elaseYurophu.

- Isiqinisekiso se-ISO(exhaswa luqinisekiso lwe-IAF) iqinisekisa ukubambelela kwethu kwiinkqubo zolawulo lomgangatho wehlabathi, ephucula ukungaguquguquki kokusebenza kunye nokuzithemba kwabathengi.

- Ukuqatshelwa kwe-ECMigxininisa ulungelelwaniso lwethu nemigangatho yobugcisa engqamene neshishini kunye nokusebenza.

Ukuba imakethi yakho okanye iprojekthi yakho ifuna izatifikethi ezongezelelweyo (umz.,API,ASME, okanye iimvume ezithe ngqo kwingingqi), iqela lethu elinamava kubuchwephesha nokuthobela liya kusebenzisana nawe ukuze ufumane izatifikethi eziyimfuneko. Silungisa iinkqubo zethu ukuhlangabezana neemfuno zakho zolawulo, siqinisekisa ukungena kwimarike engenamthungo kwizixhobo zethu.

Yethu90,000+Square meterindawo yokuvelisa yale mihla, inabasebenzi120+iingcali, izisa izisombululo zobunjineli ezilungiselelweyo kunye nobuchule bokuvelisa obuchanekileyo. Zixhotyiswe 20 amaziko machining CNC advanced, siphatha workpieces ukuya1200mmububanzi ngokuchaneka kwenqanaba lemicron (0.01mm). Iiprothokholi ezingqongqo zolawulo lomgangatho zibandakanya uhlolo olupheleleyo lwamacandelo abalulekileyo kusetyenziswa iCMM (Coordinate Measuring Machines) kunye novavanyo lomthwalo wamanqanaba amaninzi ziinjineli eziqinisekisiweyo emva kokuhlangana. Iyunithi nganye ifumana ukuqinisekiswa kokusebenza ukuze ihambelane nemigangatho ye-ASME/API kunye neenkcukacha zabathengi, exhaswa yiISO 9001-eqinisekisiweyoulawulo lomgangatho wokulandeleka, unikezelo oluthembekileyo.

Sisebenzisaifumigation-freeiziseko zokhuni oluqinileyoiqinisekiswe yi-ISO kumazwe ngamazweimigangatho yokuvalelwa. Iqiniswe ngaphakathi ngentsimbi yomjelo yokuxhasa i-dimensional-dimensional, umphandle usongelwe ngoonogada bekona bentsimbi obungqingqwa obuyi-0.8mm kwaye bukhuselwe kumalungu kusetyenziswa.imitya yentsimbi engenamanzi. Olu yilo luqinisekisa ukuxhathisa impembelelo, ukuqina kobungqina boxinzelelo, ukhuseleko lokufuma, kunye nokuthintela umhlwa kulo lonke uhambo, iqinisekisa ukuba iimpahla zakho zifika ngokukhuselekileyo.

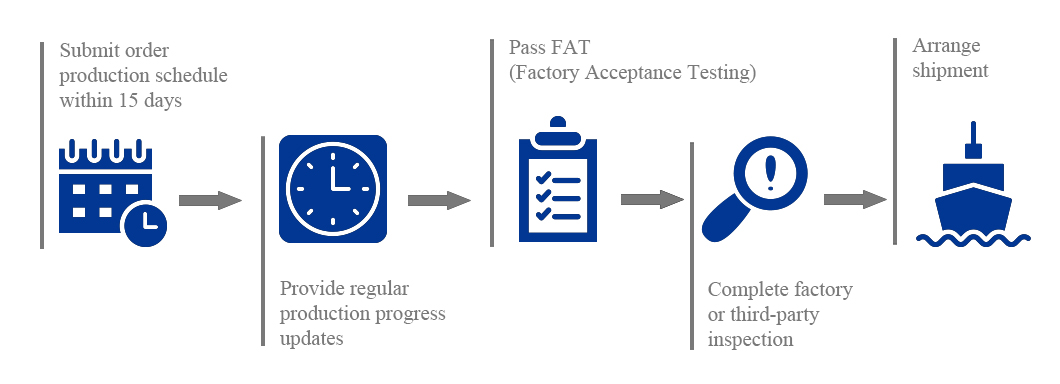

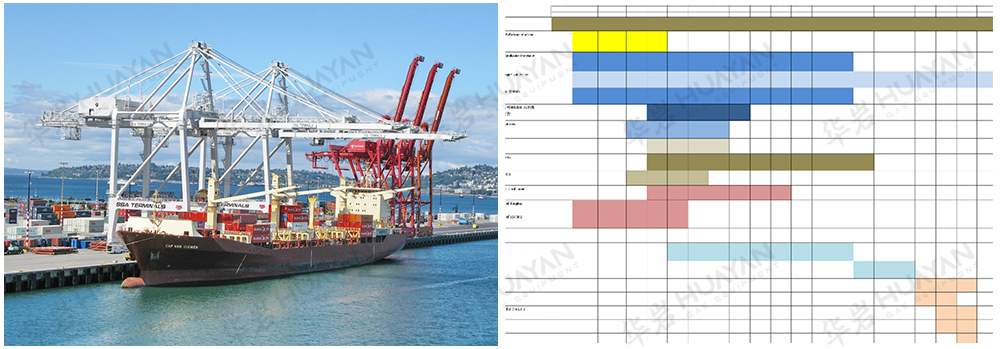

Inkampani yethu iya kuphuhlisa iishedyuli ezilungiselelwe ukuhanjiswa kweprojekthi yakho, zixhaswa zizisombululo ezihlanganisiweyo zolungiseleloezothutho zomoya, zolwandle, nezomhlaba.

Ukusebenzisa uthungelwano lwasekhaya lwaseTshayina kunye nentsebenziswano yehlabathi, siqinisekisa ukusebenza okusebenzayo okunqumla imida ngokulandela umkhondo wexesha lokwenyani, inkxaso yokukhutshwa kwezithethe, kunye nokukwazi ukugcina izinto ezibotshelelweyo. I-multi-modal bhetyebhetye iqinisekisa indleko-esebenzayo kunye nokuhanjiswa ngexesha elifanelekileyo kuzo zonke iintlobo zempahla.

1.Ufumana njani ucaphulo olukhawulezileyo lwecompressor yegesi?

1)Inqanaba lokuHamba/Umthamo : ___ Nm3/h

2)Ukufunxa/Uxinzelelo lokungena: ____ Ibha

3)Ukukhupha/Uxinzelelo lokuphuma :____ Ibha

4) Phakathi kwegesi :_____

5)I-Voltge kunye ne-Frequency : ____ V/PH/HZ

2.Lide kangakanani ixesha lokuhambisa?

Ixesha lokuhambisa lijikeleze iintsuku ezingama-30-90 .

3.Kuthekani malunga nombane weemveliso? Ngaba zinokulungiswa?

Ewe, i-voltage inokwenziwa ngokwezifiso ngokombuzo wakho.

4.Can uyamkela imiyalelo ye-OEM?

Ewe, iiodolo zeOEM zamkelekile kakhulu.

5.Ngaba uya kubonelela ngeenxalenye ezithile zoomatshini?

Ewe

Ukufakela kunye nokugunyaziswa

Ukuthumela abasebenzi benkonzo abaqeqeshiweyo kwindawo yokuqinisekisa ukufakwa kunye nokusebenza kakuhle kwezixhobo ezibonelelweyo.

Sebenzisa uqeqesho

Ufakelo lwasimahla kunye nesikhokelo sokugunyazisa, iinkonzo zobugcisa zasimahla, kunye noqeqesho lwasimahla lwabasebenzi.

Utyelelo lokulandelela rhoqo

Ukuqhuba rhoqo utyelelo lokulandelela kwisayithi kwaye unikezele ngokukhawuleza ngeenkonzo zokulandelela imveliso.

Inkonzo yobuchwephesha

Ukubonelela ngeenkonzo zobugcisa zasimahla ezifunekayo kwiprojekthi yokuhlaziya.

7 Abantu

Iqela lenkonzo yokuthengisa emva kokuthengisa.

Ireyithi yokupasa eyi-100%.

Ukufumana i-100% yezinga lokupasa komgangatho ukusuka kwimveliso kunye nokulungiswa ukuya kulawulo lwababoneleli.